Jet Boat Performance

Water Reversion/Ingestion Information

VERY IMPORTANT NOTICE, PLEASE READ CAREFULLY!!!

Reversion, what is it?

It is simply the exhaust pulse flowing backwards momentarily during the overlap phase of the camshaft at low cycling rates. During the overlap phase the piston is pushing out the last of the exhaust gases and prior to reaching top dead center (T.D.C) the intake valve and the exhaust valve is still closing. At this point in the engine cycle both valves are in the open position. At high cycling rates the inertia of the incoming intake charge and the outgoing exhaust pulses keep the exhaust flowing in the proper direction. But at low cycling rates, as the piston is pushing out the last of the exhaust gases the intake valve opens and some of the spent exhaust charge is pushed into the intake manifold. As the piston reaches T.D.C. and begins the intake stroke the exhaust valve is still not completely closed. As a result, the piston pulls from the intake and exhaust valves simultaneously causing the exhaust gases to flow in a reverse direction. This is normally not a problem until you add water into the exhaust stream. Reversion can be severe enough to stall the engine, add water to the oil, rust the exhaust seats, etc. This effect only happens at idle speeds, but remember that during shut down the engine encounters the greatest reversion.

For these reasons Rewarder Custom Headers has guidelines for camshaft selection. Our guidelines are based on 454 c.i. with a 285 degree camshaft (242 at .050), on a 114 degree lobe center. Larger cams may cause reversion. These figures are just guidelines. Cubic inches, valve size, exhaust valve timing, etc., all will have an effect on reversion. The only true test is to run the engine with the headers attached, shut it down, remove the headers and check for water residue in the header ports to check for an occurrence of water reversion.

Your Other Option Is:

Install extended dry pipes

This option substantially reduces if not eliminates water reversion. With this option you can adjust where water is introduced into the exhaust stream. Remember the longer you extend the dry pipe the louder the system becomes.

Header Water "Reversion" courtesy of Rewarder headers

JET BOAT WATER INJECTED HEADER INSTALLATION

1. Install stainless steel lines to headers.

2. Install headers on engine.

3. Make sure there is not a thermostat in the housing or any other type of water temperature control.

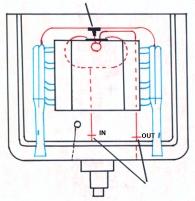

4. Install "T" stainless steel control valve in one line of the two lines on the thermostat housing. Connect the T end to header. Lines to headers should be approximately 2" long. T valve is marked < to headers >

5. The other lines from the thermostat housing are your by-pass line. Run it overboard with a 1/2" brass gate valve. (plumbing type)

6. The gate valve is necessary so that you can regulate the amount of water you discharge. It also is to regulate what RPM your water is injected into the headers.

Example: gate valve is wide open and water comes in at 3000 RPM. To make the water come in at 1500 to 2000, close gate valve approximately 1/3.

7. How your water injected headers work:

A. Your headers should be dry at idle (and hot). The water is going out by-pass line overboard.

B. The water is injected by approximately 1500 RPM when you are on the throttle. When you back off the throttle, the stainless steel automatic control valve should close and the headers should go dry. When you get back on the throttle, water should be automatically injected again. If it does not work in this manner, something is hooked up wrong or your valve is plugged.

JET DRIVE APPLICATION (over transom only)